Ever watched a vibrant outdoor banner fade to nothing after just a few months in the sun? That frustration drives countless business owners and sign makers to discover the game-changing benefits of vinyl lamination. This protective process transforms ordinary printed vinyl into durable, long-lasting graphics that maintain their stunning appearance regardless of what nature throws their way.

Understanding when and why to use vinyl lamination can mean the difference between graphics that last months versus those that endure for years. Whether you’re creating vehicle wraps, outdoor signage, or indoor displays, knowing the right applications for lamination helps you deliver professional results that exceed client expectations.

Key Takeaways

- Vinyl lamination provides essential protection for outdoor graphics exposed to UV radiation, weather, and environmental pollutants

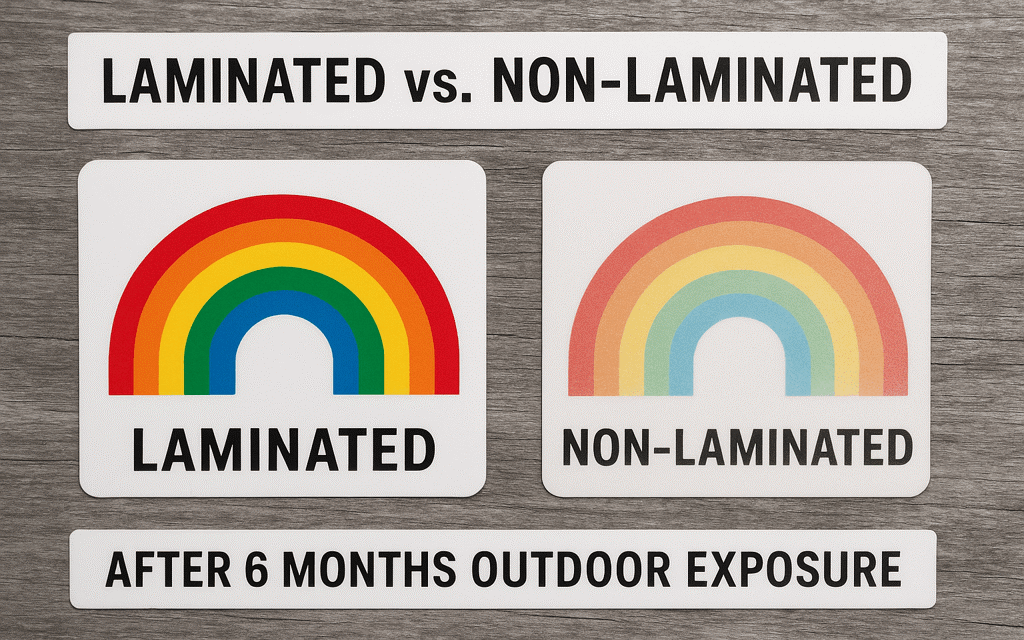

- Laminated graphics typically last 3-5 times longer than unprotected alternatives, providing significant long-term cost savings

- Different laminate types (gloss, matte, textured) offer specific aesthetic and functional benefits for various applications

- High-traffic indoor environments benefit from lamination’s easy cleaning and durability advantages

- Proper application techniques and environmental conditions are crucial for achieving optimal lamination performance

- The 20-30% additional cost of lamination often pays for itself through extended lifespan and reduced maintenance requirements

- Professional consultation helps match laminate specifications to specific project requirements and environmental conditions

Table of Contents

What Is Vinyl Lamination and Why Does It Matter?

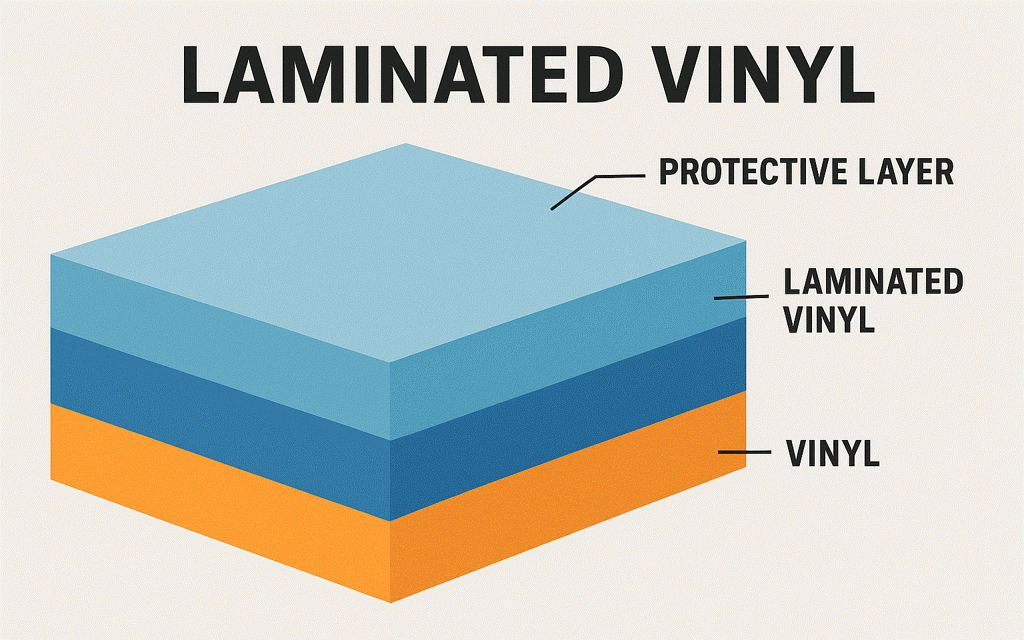

Vinyl lamination involves applying a thin, transparent protective film over printed vinyl graphics. This additional layer serves as a shield against environmental factors that typically degrade print quality over time. The lamination process bonds seamlessly with the printed surface, creating a unified protective barrier that extends the life of your graphics significantly.

The science behind lamination effectiveness lies in its ability to block harmful UV rays while providing physical protection against scratches, moisture, and chemical exposure. Professional-grade laminates contain UV inhibitors that prevent the photodegradation process that causes colors to fade and lose their vibrancy.

Essential Scenarios for Vinyl Lamination

Outdoor Applications That Demand Protection

Outdoor environments present the harshest conditions for printed graphics. Vinyl lamination becomes absolutely crucial when your graphics face constant exposure to UV radiation, temperature extremes, rain, wind, and airborne pollutants. Vehicle wraps represent one of the most demanding applications, where graphics endure highway speeds, car washes, and daily temperature cycling.

Building signage and storefront graphics benefit tremendously from lamination, especially when positioned in direct sunlight. The protective layer prevents the gradual color shift that makes professional signage look aged and unprofessional within months of installation.

High-Traffic Indoor Environments

While outdoor use drives most lamination decisions, indoor applications shouldn’t be overlooked. Retail environments, hospitals, schools, and public buildings subject graphics to frequent cleaning, accidental contact, and general wear. Vinyl lamination in these settings provides easier maintenance and extends graphic lifespan significantly.

Wayfinding systems in busy facilities particularly benefit from lamination’s protective properties. These graphics face constant touching, cleaning with commercial products, and potential vandalism attempts.

Lamination Types and Their Specific Benefits

|

Lamination Type |

Best Applications |

Key Benefits |

Typical Lifespan |

|

Gloss Laminate |

Vehicle wraps, retail signage |

Enhanced color vibrancy, easy cleaning |

7-10 years |

|

Matte Laminate |

Indoor displays, anti-glare applications |

Reduced glare, sophisticated appearance |

5-8 years |

|

Textured Laminate |

Architectural graphics, specialty applications |

Unique tactile feel, premium appearance |

5-7 years |

|

Anti-graffiti Laminate |

Public signage, transit graphics |

Graffiti removal without damage |

3-5 years |

Visual Enhancement Through Lamination

Beyond protection, vinyl lamination dramatically improves the visual impact of printed graphics. Gloss laminates intensify colors, making them appear more saturated and vibrant. This enhancement proves particularly valuable for marketing materials where visual impact drives customer engagement.

Matte laminates offer a completely different aesthetic, providing a sophisticated, non-reflective surface that works exceptionally well in environments with challenging lighting conditions. Museums, galleries, and upscale retail environments often prefer matte finishes for their refined appearance.

The Science of Protection: How Lamination Works

Understanding the protective mechanisms of vinyl lamination helps explain its effectiveness across different applications. UV inhibitors within the laminate absorb harmful radiation before it reaches the printed inks, preventing the molecular breakdown that causes fading.

The physical barrier created by lamination prevents moisture penetration, which otherwise leads to ink bleeding, substrate degradation, and adhesive failure. This moisture protection proves especially critical in humid climates or applications involving regular cleaning.

Chemical resistance represents another crucial benefit, particularly in industrial environments or areas where cleaning solvents might contact the graphics. The laminate layer prevents these chemicals from reaching and damaging the printed surface.

Cost-Benefit Analysis: When Lamination Pays Off

|

Scenario |

Without Lamination |

With Vinyl Lamination |

Cost Savings |

|

Outdoor banner (1 year) |

Replace 3-4 times |

Replace once |

60-75% |

|

Vehicle wrap |

Fade in 2-3 years |

Maintain quality 7+ years |

200-300% |

|

Retail signage |

Monthly touch-ups |

Annual inspection |

80-90% |

|

Wayfinding system |

Biannual replacement |

5-year lifespan |

150-250% |

The initial investment in vinyl lamination typically represents 20-30% additional cost over unlaminated graphics. However, the extended lifespan and reduced maintenance requirements often result in significant long-term savings, especially for businesses requiring consistent brand presentation.

Professional Application Techniques

Proper lamination application requires specific environmental conditions and techniques to achieve optimal results. Temperature and humidity control during application prevents bubbling, wrinkling, and adhesion problems that compromise the protective benefits.

The timing of lamination application also affects final quality. Most professionals recommend allowing printed vinyl to outgas for 24-48 hours before lamination, ensuring proper adhesion and preventing trapped solvents from causing future problems.

Surface preparation plays a crucial role in lamination success. Any dust, oils, or imperfections on the printed surface will telegraph through the laminate, creating visible defects and potential failure points.

Maintenance and Longevity Expectations

Properly applied vinyl lamination significantly reduces maintenance requirements while extending graphic lifespan. Regular cleaning with appropriate solutions maintains appearance without damaging the protective layer.

Expected lifespans vary based on environmental conditions, but laminated outdoor graphics typically last 3-5 times longer than unprotected alternatives. Indoor applications can exceed 10 years with proper care and appropriate laminate selection.

Environmental factors affecting longevity include UV exposure intensity, temperature fluctuations, humidity levels, and exposure to chemicals or pollutants. Understanding these factors helps set realistic client expectations and choose appropriate laminate specifications.

Making the Right Choice for Your Project

Selecting appropriate vinyl lamination depends on multiple factors including intended lifespan, environmental conditions, aesthetic requirements, and budget constraints. Professional consultation often proves valuable for complex projects or challenging environments.

Consider the total cost of ownership rather than just initial expenses. Projects requiring frequent replacement or maintenance often benefit significantly from lamination investment, while short-term applications might not justify the additional cost.

Quality considerations extend beyond price to include laminate specifications, application expertise, and manufacturer warranties. Choosing reputable suppliers and experienced installers prevents costly failures and ensures expected performance.