The heat transfer vinyl (HTV) market is experiencing unprecedented growth, with industry projections showing it will reach $4 billion by 2027, demonstrating just how popular vinyl crafts have become among creators worldwide. This explosive expansion reflects the growing demand for custom designs, personalized apparel, and unique DIY projects that allow both hobbyists and professionals to express their creativity through various heat transfer vinyl types.

Whether you’re creating personalized t-shirt vinyl designs for family reunions, designing custom uniforms for local sports teams using your Cricut machine, or building a thriving crafting business with Silhouette cutting tools, understanding the nuances of different types of heat transfer vinyl becomes absolutely crucial for achieving professional results. The right type of vinyl selection can transform an ordinary project into something extraordinary, while the wrong choice might lead to peeling, cracking, or fading designs that disappoint both creators and recipients.

Leading brand of heat transfer vinyl manufacturers like Siser EasyWeed, Cricut, and Expressions Vinyl have revolutionized the industry by offering extensive collections that cater to every conceivable project need, from basic everyday applications to specialized requirements that demand unique properties. This comprehensive guide will walk you through everything you need to know about heat transfer vinyl types, empowering you to make informed decisions that result in stunning, durable designs every single time.

Key Takeaways

- Mastering different types of HTV is essential for crafting success and professional-quality results

- The booming HTV industry reflects the increasing popularity of personalized crafting and custom designs

- Premium brands like Siser EasyWeed and Cricut brand offer diverse options tailored to various project requirements and skill levels

- Selecting the appropriate type of heat transfer vinyl significantly improves both design quality and longevity of finished projects

- This detailed guide explores specific heat transfer vinyl types and their optimal applications for maximum success

Table of Contents

Understanding Heat Transfer Vinyl

Heat transfer vinyl, commonly abbreviated as HTV, represents a revolutionary craft vinyl material specifically engineered for applying custom designs onto fabric surfaces with precision and durability. This versatile material consists of a specially formulated polymer that activates under controlled heat and pressure conditions, creating a permanent bond with textile fibers that withstands regular wear and washing cycles.

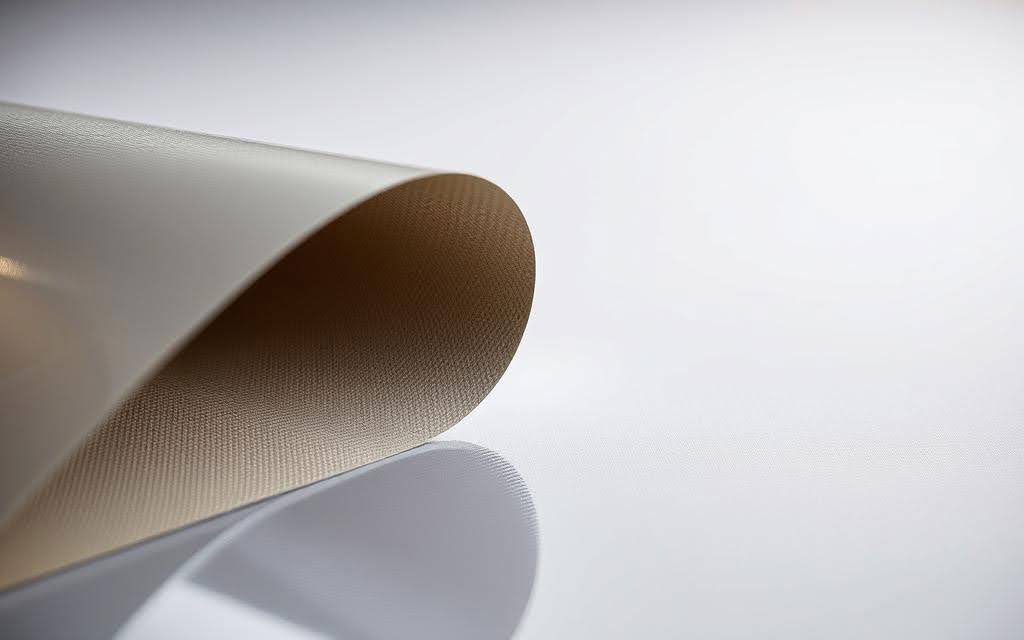

The fundamental structure of HTV includes two critical components working in harmony: the adhesive backing that ensures secure attachment to fabric, and the carrier sheet that protects and positions the design during the heat application process. The adhesive backing contains heat-activated polymers that become tacky when exposed to specific different temperatures, while the carrier sheet provides stability and allows for precise placement before heat pressing.

The typical workflow begins with a cutting machine like a Cricut device or Silhouette cutter precisely cutting your desired design from the vinyl sheet, following digital patterns created in Cricut Design Space or similar software. After cutting, crafters carefully peel away excess material around the design in a process called weeding, leaving only the intended design elements attached to the carrier sheet for easy to weed removal.

The final application involves using a heat press or household iron-on method to apply controlled heat and pressure, activating the adhesive and permanently bonding the vinyl to the fabric surface. This process creates professional-quality, washable designs that maintain their appearance and integrity through countless wear and wash cycles when proper techniques are employed with quality vinyl products.

What is Heat Transfer Vinyl?

Modern heat transfer vinyl is primarily manufactured from two distinct polymer materials: polyurethane (PU) and polyvinyl chloride (PVC), each offering unique characteristics that make them suitable for different materials and project requirements. Polyurethane-based vinyls are renowned for their exceptional softness and flexibility, making them ideal for fabric projects where comfort and natural drape are paramount, such as children’s clothing and everyday wear garments made from cotton and polyester blends.

Polyvinyl chloride variants tend to be slightly thicker and more economical, offering excellent durability and vibrant colors that make them perfect for a wide range of colors in projects where cost-effectiveness meets quality performance. The manufacturing process involves creating thin, flexible sheets and rolls infused with pigments and additives that enhance specific properties like stretch capability, glitter effects, or specialty finishes that create unique texture variations.

The application process requires cutting designs in mirror image (reverse) to ensure proper orientation after application, making the weeding process more intuitive and reducing errors when using Cricut or other cutting machines. This reverse cutting technique is crucial for text-based designs and ensures that letters and graphics appear correctly oriented on the finished garment after the heat application process.

After weeding away unwanted material, the remaining design elements are transferred to fabric using heat-activated permanent adhesive vinyl properties that create a molecular bond with textile fibers. This bonding process results in designs that become an integral part of the fabric rather than merely sitting on top of it, ensuring longevity and professional appearance across many different types of applications.

Popular Types of Heat Transfer Vinyl

Understanding the diverse landscape of heat transfer vinyl types empowers crafters to select the perfect material for every project, ensuring optimal results that meet both aesthetic and functional requirements. Each type of vinyl offers distinct characteristics, application methods, and performance benefits that cater to specific design needs and fabric types compatibility requirements.

Standard HTV

Standard HTV serves as the cornerstone of most vinyl projects, offering reliable performance and versatility that makes it indispensable for both beginners and experienced crafters working with different types of vinyl. This foundational type of heat transfer vinyl excels in detailed designs due to its smooth cutting characteristics and easy to weed properties that simplify the removal of intricate design elements without tearing or stretching when using heat transfer vinyl techniques.

The exceptional adhesion properties of standard HTV make it compatible with most common fabric types, including cotton, polyester, and cotton-polyester blends, ensuring reliable bonding across diverse textile applications. Its moderate thickness strikes the perfect balance between durability and flexibility, allowing designs to move naturally with fabric while maintaining structural integrity through repeated washing and wearing cycles.

Standard HTV vinyl is available in an impressive range of colors from basic primaries to sophisticated specialty shades, enabling crafters to match brand colors, coordinate with existing designs, or create striking contrast effects. The matte finish provides a professional appearance that doesn’t compete with design elements while offering excellent opacity that covers underlying fabric colors completely across different colors and fabric combinations.

Stretch HTV

Stretch HTV represents a specialized category designed specifically for projects requiring exceptional flexibility and resilience, making it the preferred choice for athletic wear, activewear, and garments that experience significant movement during use. This innovative type of vinyl contains elastomeric additives that allow it to stretch considerably without cracking, tearing, or losing adhesion to the underlying fabric.

The unique formulation ensures that designs maintain their appearance and integrity even when applied to highly elastic fabrics like spandex, lycra, and performance blends commonly used in sportswear and yoga apparel. The adhesive system is specially engineered to bond with stretch fabrics while maintaining flexibility, preventing the common problem of rigid designs that crack under stress during active use.

Athletes and fitness enthusiasts particularly appreciate stretch HTV because it moves seamlessly with their bodies during physical activity, eliminating the discomfort and restriction often associated with traditional vinyl applications. The material retains its stretch properties through countless wash and wear cycles, ensuring that team uniforms and personal athletic wear maintain their professional appearance season after season.

Glitter HTV

Glitter HTV transforms ordinary projects into dazzling showpieces that catch light and attention with every movement, making it perfect for special occasions, celebrations, and designs that demand visual impact. The manufacturing process involves embedding fine glitter particles within the vinyl matrix, ensuring that sparkle elements remain securely attached rather than shedding onto clothing or surroundings during heat transfer vinyl projects.

The specialized adhesive formulation accommodates the irregular surface created by glitter particles while maintaining strong bonding with fabric fibers, preventing delamination and ensuring long-lasting sparkle that survives repeated washing cycles. Modern glitter HTV maintains excellent cutting precision despite the embedded particles, allowing for detailed designs and intricate patterns that rival smooth vinyl varieties when processed through quality cutting machines.

Color options span the spectrum from subtle champagne and rose gold to bold jewel tones and rainbow effects, providing a variety of colors that enable designers to create everything from elegant monograms to eye-catching party wear. The durability of quality glitter HTV ensures that special occasion garments maintain their glamorous appearance through multiple events and cleaning cycles.

Metallic Heat Transfer Vinyl

Metallic heat transfer vinyl introduces sophisticated shimmer and modern elegance to designs through advanced surface treatments that create mirror-like finishes with exceptional depth and richness. Unlike simple metallic paints or foils, true metallic HTV incorporates reflective elements throughout the material structure, ensuring consistent appearance from every viewing angle and lighting condition.

The smooth, non-textured surface of metallic heat transfer vinyl makes it particularly suitable for detailed designs and fine text applications where precision and clarity are essential for professional results. The material cuts cleanly without the irregularities sometimes associated with textured vinyls, allowing for sharp edges and crisp design elements that maintain their definition after heat application.

Professional applications frequently utilize metallic heat transfer vinyl for corporate logos, awards, and formal wear where sophisticated appearance is paramount. The material’s ability to maintain its reflective properties through commercial washing makes it ideal for uniforms, promotional apparel, and branded merchandise that requires lasting visual impact across many types of heat transfer applications.

Heat Transfer Vinyl Types and Their Applications

Selecting the most appropriate heat transfer vinyl types for specific fabric combinations and intended applications requires understanding the complex interactions between vinyl chemistry, fabric composition, and end-use requirements. Different materials respond uniquely to various HTV formulations, making informed selection crucial for achieving optimal adhesion, durability, and aesthetic results when making heat transfer vinyl projects.

Vinyl Compatibility Chart

Fabric Type | Standard HTV | Stretch HTV | Glitter HTV | Metallic HTV | Specialty Vinyl |

100% Cotton | Excellent | Good | Excellent | Excellent | Varies by type |

Cotton/Poly Blend | Excellent | Good | Good | Excellent | Good |

100% Polyester | Good | Fair | Fair | Good | Varies by type |

Spandex/Lycra | Fair | Excellent | Fair | Fair | Limited options |

Athletic/Performance | Fair | Excellent | Fair | Good | Stretch specialty only |

Denim | Good | Good | Excellent | Excellent | Depends on weight |

Application Temperature Guide

HTV Type | Temperature Range | Press Time | Pressure Level | Peel Method |

Standard HTV | 300-320°F | 10-15 seconds | Medium | Hot or cold peel |

Stretch HTV | 275-300°F | 15-20 seconds | Light-Medium | Cold peel only |

Glitter HTV | 320-340°F | 20-25 seconds | Firm | Cold peel only |

Metallic HTV | 300-320°F | 15-20 seconds | Medium-Firm | Hot peel preferred |

Specialty Vinyl | Varies | Varies | Varies | Check manufacturer |

Choosing the Right HTV for Your Fabric

Before committing to any heat transfer vinyl types, conducting thorough fabric analysis becomes essential for predicting compatibility and performance outcomes when using heat transfer vinyl in various applications. Cotton and cotton-polyester blends generally offer the most forgiving application surface, accepting most HTV varieties with reliable results when proper heat press temperature and pressure settings are maintained consistently.

Synthetic fabrics like polyester require more careful consideration, as some varieties may be sensitive to high temperatures or may not provide optimal adhesion surfaces for certain vinyl formulations. Fabric types with stretch properties demand specialized attention, with Stretch HTV being virtually mandatory for maintaining design integrity during fabric elongation and recovery cycles.

The intended use environment also influences vinyl selection, with items destined for frequent washing requiring more durable formulations from reputable brand of heat transfer vinyl manufacturers, while decorative pieces may prioritize aesthetic properties over long-term durability. Understanding these relationships enables crafters to make informed decisions that result in successful HTV projects every time.

Working with Heat Transfer Vinyl

Mastering heat transfer vinyl application requires assembling the right tools, understanding proper techniques, and developing consistent processes that produce professional results reliably when using a heat press or alternative application methods. Success depends on attention to detail during every phase, from initial design conception through final quality inspection of the completed vinyl projects.

Essential equipment includes precision cutting machines capable of handling various vinyl thicknesses and compositions, professional-grade heat presses that maintain consistent temperature and pressure, and specialized tools designed specifically for vinyl manipulation and application. Quality tools represent an investment that pays dividends through improved results and reduced material waste across many types of heat transfer applications.

Tools Needed for HTV Projects

Professional vinyl projects demand specific tools designed to handle the unique requirements of heat transfer vinyl materials and ensure precise, repeatable results when creating custom designs. A reliable cutting machine serves as the foundation of any serious HTV operation, with options ranging from entry-level Cricut units suitable for hobbyists to commercial-grade machines capable of handling high-volume production requirements.

Weeding tools constitute another critical category, with various blade shapes and sizes optimized for different design complexities and vinyl types to ensure easy to weed removal of excess material. Fine-tip weeders excel at removing small interior elements, while broader tools efficiently clear large areas of unwanted material from vinyl sheets and vinyl rolls.

Transfer tape or transfer paper becomes essential for positioning and applying multi-element designs with precision and confidence, especially when working with detailed designs that require careful alignment. Heat-resistant tape prevents design elements from shifting during the pressing process, ensuring accurate registration and preventing costly mistakes during heat application.

Setting Up Your Heat Press

Proper heat press calibration forms the foundation of consistent, professional results that meet or exceed client expectations and personal quality standards when using a heat press for heat transfer vinyl projects. Heat press temperature accuracy becomes crucial, as variations of even 10-15 degrees can significantly impact adhesion quality and vinyl performance, potentially causing premature failure or poor initial bonding.

Pressure calibration ensures even contact across the entire design area, preventing weak spots that might fail prematurely while avoiding excessive force that could damage delicate fabrics or create unwanted texture impressions. Regular calibration checks using infrared thermometers and pressure-sensitive papers help maintain optimal performance over time when working with different types of HTV.

Test pressing on fabric scraps before committing to final projects allows fine-tuning of settings for optimal results with specific vinyl and fabric combinations. This practice prevents costly mistakes and builds confidence in the process while establishing documented settings for future reference and consistency across vinyl projects.

Heat Transfer Vinyl Project Durability and Care

Extending the lifespan of HTV projects requires implementing proper care protocols that protect the vinyl–fabric bond while maintaining the aesthetic qualities that make custom designs appealing to end users. Understanding the factors that contribute to vinyl degradation enables crafters to provide clients with care instructions that maximize design longevity and customer satisfaction across different types of heat transfer applications.

Durability Expectations by Vinyl Type

HTV Type | Expected Lifespan | Wash Cycles | Care Level | Common Issues |

Standard HTV | 50+ washes | 50-75 cycles | Low | Edge lifting, fading |

Stretch HTV | 40+ washes | 40-60 cycles | Medium | Overstretching damage |

Glitter HTV | 30+ washes | 30-50 cycles | High | Glitter loss, cracking |

Metallic HTV | 45+ washes | 45-65 cycles | Medium | Surface scratching |

Specialty Vinyl | Varies | 20-40 cycles | High | Type-specific issues |

Washing and Maintenance Best Practices

Implementing proper laundering techniques significantly extends the functional life of heat transfer vinyl designs while preserving their visual appeal and structural integrity when working with quality vinyl products. Turning garments inside out before washing provides crucial protection against mechanical abrasion from other clothing items and washer surfaces that can gradually degrade vinyl surfaces over time.

Cold water washing minimizes thermal stress on both vinyl and adhesive components, preventing premature bond failure and color shifts that can occur when exposed to elevated different temperatures repeatedly. Gentle cycle settings reduce mechanical stress while still providing adequate cleaning action for most soiling conditions encountered in everyday wear.

Air drying represents the safest option for preserving vinyl integrity, though low-heat machine drying remains acceptable when time constraints make air drying impractical for busy households. Avoiding fabric softeners and bleach-based products protects vinyl surfaces from chemical degradation that can compromise both appearance and adhesion over time.

Advanced Heat Transfer Vinyl Techniques

Mastering advanced heat transfer vinyl types applications opens creative possibilities that distinguish professional work from amateur attempts while expanding service offerings and design complexity capabilities. These techniques require patience, practice, and attention to detail but yield impressive results that command premium pricing and client satisfaction when creating custom designs.

Layering Techniques with HTV

Layering multiple vinyl colors and types creates dimensional designs with visual depth and complexity that single-layer applications cannot achieve when working with different types of heat transfer materials. Successful layering requires understanding how different types of HTV formulations interact under heat and pressure, with some combinations yielding superior results while others may cause adhesion problems or premature failure.

Standard HTV provides an excellent base layer due to its reliable adhesion properties and compatibility with most overlay materials from various vinyl products manufacturers. However, layering glitter HTV or other textured varieties requires careful consideration of heat press temperature settings and pressing sequences to ensure proper bonding without damaging underlying layers.

Color-changing vinyl and holographic vinyls add spectacular visual effects when properly layered with complementary base colors, creating designs that shift and sparkle with movement and lighting changes. Planning layer sequences before beginning cutting prevents errors and ensures optimal visual impact in the finished design when working with pattern vinyl and other specialty vinyl types.

Specialty Heat Transfer Vinyl Types

Holographic HTV

Holographic vinyl produces mesmerizing color shifts that change with viewing angle and lighting conditions, making it perfect for performance costumes, promotional items, and fashion statements that demand attention. This specialty vinyl requires specific application techniques and heat press temperature settings to achieve optimal results without damaging the reflective surface properties.

The unique optical properties of holographic HTV create rainbow-like effects that shift through the spectrum as the viewing angle changes, providing dynamic visual interest that static colors cannot match. Quality holographic vinyl maintains its optical properties through multiple wash cycles when properly applied using appropriate heat and pressure settings.

Flock Heat Transfer Vinyl

Flock heat transfer vinyl creates a distinctive raised, velvety texture that mimics the feel of suede or felt, adding tactile dimension to designs that enhances both visual and sensory appeal. This type of heat transfer vinyl excels in applications where texture variation creates design interest, such as sports team logos, decorative elements, and vintage-inspired graphics.

The unique texture of flock HTV makes it particularly suitable for layering applications where dimensional contrast enhances overall design impact. Proper weeding techniques become crucial with flock vinyl, as the raised surface can make removal of unwanted material more challenging than with smooth vinyl varieties.

Glow in the Dark and Color-Changing Options

Glow-in-the-dark vinyl charges during daylight exposure and releases stored energy as visible light in dark conditions, creating safety applications for outdoor workers, children’s clothing, and novelty items that serve both functional and aesthetic purposes. Color-changing vinyl responds to temperature variations, creating dynamic effects that shift with environmental conditions or body heat.

These specialty vinyl types require specific application techniques and may have different durability characteristics compared to standard HTV options. Understanding the unique properties of each specialty vinyl ensures successful application and realistic expectations for performance and longevity.

Working with Different Brands

Siser EasyWeed

Siser EasyWeed represents the gold standard in heat transfer vinyl quality and reliability, offering consistent performance across a wide range of colors and finishes that make it a favorite among both hobbyists and professionals. The ease of use and reliable weeding characteristics of Siser EasyWeed make it an excellent choice for beginners while providing the quality that professionals demand.

The vinyl is best in class for detailed designs due to its precise cutting characteristics and clean release properties that minimize waste and maximize design quality. Siser EasyWeed maintains excellent adhesion across different materials while providing the flexibility needed for comfortable wear.

Cricut Iron-On

Cricut iron-on vinyl integrates seamlessly with Cricut machines and Cricut Design Space software, providing optimized cutting and application settings that ensure consistent results when using Cricut equipment. The Cricut brand offers extensive color selection and specialty finishes that coordinate with their machine capabilities and design software.

Cricut products include smart materials that eliminate the need for cutting mats, streamlining the workflow for high-volume projects while maintaining the precision needed for detailed designs. The integration between Cricut iron-on materials and equipment simplifies the learning curve for newcomers to vinyl crafts.

Expressions Vinyl

Expressions Vinyl provides an extensive selection of quality heat transfer vinyl options including unique colors, patterns, and specialty finishes not readily available from other manufacturers. Their printable vinyl options enable incorporation of photographic elements and complex graphics that expand creative possibilities beyond solid color applications.

The variety of colors and finishes available from Expressions Vinyl makes it possible to match virtually any design requirement while maintaining consistent quality across different types of vinyl. Their customer service and educational resources support successful project completion for crafters at all skill levels.

Final Recommendations for Heat Transfer Vinyl Excellence

This comprehensive exploration of heat transfer vinyl types demonstrates the incredible versatility and creative potential available to modern crafters, from hobbyists creating personalized gifts to professionals building thriving custom apparel businesses using quality heat transfer vinyl materials. The wide array of available different types of HTV ensures that virtually any design concept can be realized with appropriate material selection and application techniques.

Success with heat transfer vinyl projects depends on understanding the unique characteristics of each type of vinyl, selecting appropriate materials for specific applications, and maintaining consistent processes that produce reliable, professional results. Whether working with best heat transfer vinyl brands like Siser EasyWeed or exploring newer options in the marketplace, knowledge and practice remain the keys to achieving outstanding outcomes.

The HTV industry continues evolving with new formulations, improved application methods, and innovative specialty vinyl materials that expand creative possibilities while simplifying application processes for using heat transfer vinyl. Staying current with these developments while mastering fundamental techniques ensures continued success and satisfaction in vinyl crafts and custom design applications.

Quality heat transfer vinyl combined with proper techniques, appropriate tools, and careful attention to detail enables creators to produce stunning, durable designs that exceed client expectations and provide lasting satisfaction. The investment in learning these skills pays dividends through improved results, reduced waste, and the confidence to tackle increasingly complex and rewarding vinyl projects that showcase creativity and technical expertise across many different types of applications.